The swanky new sea bridge at Pamban glistens in the summer sun. Dubbed as an engineering marvel, this imposing lifting-span structure facilitates better train operations in the Palk Strait, connecting Ramanathapuram with the Rameswaram island.

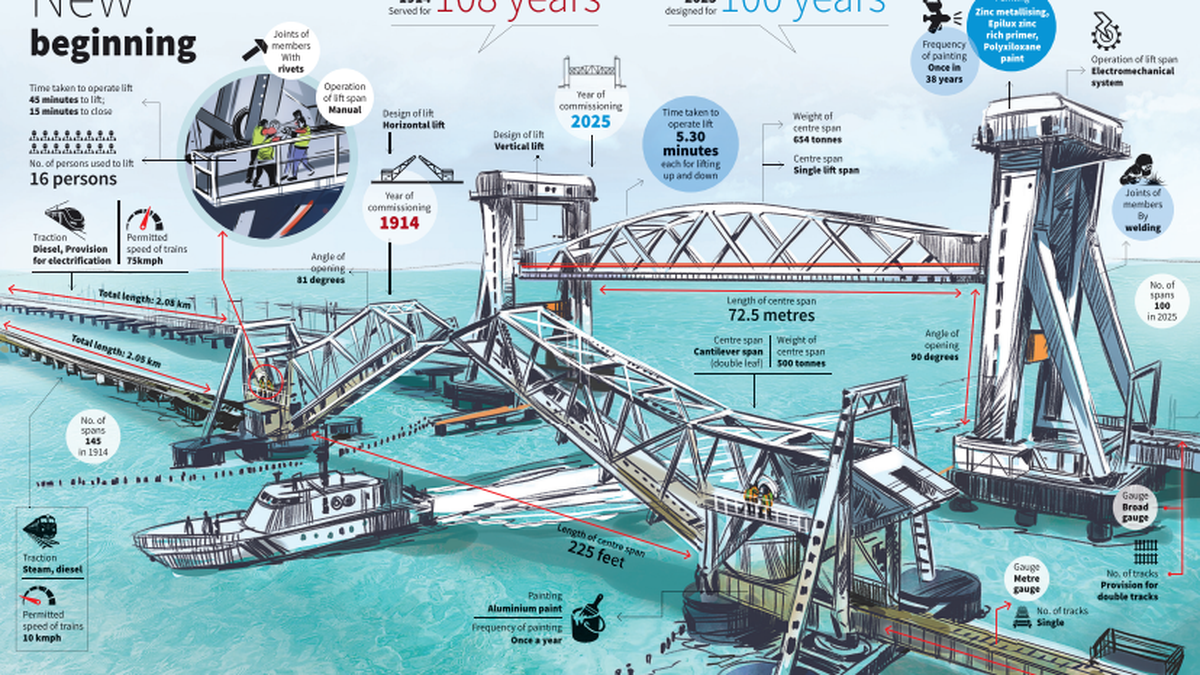

The British-era old Pamban Rail Bridge, comprising two cantilever bridges, had to be replaced because its highly corroded centre span made the structure vulnerable. All trains had to slow down while passing through the bridge. When Southern Railway decided to spruce things up, it wanted the new lift span as a single piece, between two sub-structures.

New Pamban bridge in Tamil Nadu set for inauguration by PM Modi live updates

Search for design

As India did not have any bridge with a lift span, other than the Pamban bridge, engineers of Rail Vikas Nigam Limited (RVNL), which implemented the new bridge project, scouted for the best design. They inspected some 2,000 functional bridges in the U.S., RVNL Chairman and Managing Director Pradeep Gaur said. Among the three choices, including a swing bridge and a single-leaf bascule bridge, the vertical lift span best suited the Indian Railways’ requirements of stability and cost-effectiveness. Then the engineers looked for a state-of-the-art design with the world’s best practices which could also tackle the issue of corrosion, as Pamban is situated in the world’s second most corrosive environment, in the Bay of Bengal.

Spanish company TYPSA was appointed the consultant for the project. Its design was proof-checked by IIT-Madras. Subsequently, it was altered by IIT-Bombay for improving the stability with an additional 60 tonnes of steel in the vertical lift section. As a consequence, machinery and specifications had to be changed, and it took longer than anticipated. The design change and the suspension of construction due to the COVID-19 pandemic also affected the supply of materials for several months. “In one case, after producing 500 composite sleepers out of 2,500 sleepers ordered by the RVNL, the company in the U.S. was shut because of COVID-19,” Mr. Gaur pointed out.

Challenges

The engineers and the workers faced several challenges at the worksite, including space constraints in the sea and strong winds that held up the installation of the machinery. The biggest challenge was the narrow approach road to the site from the Pamban side through which materials, especially huge equipment, were transported.

Besides, the shallow but rough sea at the site and the monsoon which allowed work only for six months a year threw up major challenges, RVNL consultant S. Anbalagan said. “The materials could be moved to the site only by barge. But the barges would run aground during low tide, and we would wait for high tide to move them again,” he added.

Project cost goes up

The two-year delay and the consequent inflation drove up the project cost from ₹279 crore to ₹531 crore. However, Mr. Gaur said the longest vertical bridge in Hamburg, Germany, measuring 133 metres and commissioned in 2020, was constructed in five years, though its total length was 257 metres. However, the Pamban bridge, which is 2.08-km long with a 72.5-metre vertical bridge, was completed in the same time frame, he said. “If we have to build a similar bridge, we can do it in three years with the experience gained in the construction of this bridge,” he said.

As corrosion was the old Pamban bridge’s Achilles heel, a lot of precautionary measures were taken to tackle it in the new bridge. The RVNL team had visited Florida, the most corrosive part of the world, to study the painting scheme. The officials came up with a proven painting technology used around the world. “The scheme with zinc metallising, Epilux zinc rich primer, and Polysiloxane paint has withstood corrosion for 40 years, though the design period for one coat of painting under the scheme is only 38 years,” Mr. Gaur said.

The scheme is being used for the first time by the Indian Railways. “If proper inspection and maintenance is done, the life of this coat of painting can be extended by 40%: the first coat of painting can protect the bridge for at least 55 years,” he said.

While the Indian Railways paints its steel structures once in five years, the old Pamban bridge became so unstable owing to corrosion that painting was done once in three months. “That way, I am confident the new bridge would require the next coat of paint only after 50 years,” he said.

Mr. Gaur was all praise for the Spanish designer behind the structural design of the lift span. “The design has a huge significance. It has no rough edges and everything has been rounded off to avoid water ingression or stagnation [anywhere over it]. The lift span has been made with a box-type section and it is closed to prevent moisture intrusion,” he added. The smoothening of the surface has removed the edges, thus stymieing corrosion. He credited the designer with having taken care of not only the painting scheme but also the structural aspect to minimise the chances of corrosion.

The RVNL fabricated all the steel structures — including the girders, 34-metre-high towers of the vertical lift, and its counter-weights — at Sathirakudi, 30 km away from the construction site. “We chose a farther place as it was very important to fabricate the steel structures at least 50 km away from the coast to avoid corrosion. The RVNL has handed over the bridge to Southern Railway and the engineers have been trained in operating the vertical lift,” he said.

The RVNL used 3.38 lakh bags of cement for the pile foundation, which has an average depth of 38 metres below the seabed. It used 5,772 metric tonnes of stainless steel reinforcement and 4,500 tonnes of structural steel. “Except for the gears, brakes, and spherical bearings, all the materials used for the new bridge have been sourced domestically. The imported materials would constitute only 2%-3% of the total materials,” he added.

Furthermore, this imposing structure has been constructed by Indian contractors, though it has been designed by a Spanish company. Even the software for operating the vertical lift span has been developed indigenously. “This is a real case study in displaying the prowess of India in [carrying out the construction] of such an iconic and unique bridge,” he said. Mr. Gaur was quick to add that even the design of the vertical lift is now owned by the Indian Railways.

Longer lifespan

The new bridge has been designed for 25-tonne axle loading, the maximum loading factor in the Indian Railways (except on the dedicated freight corridor). The structure has been designed for operating trains without any speed restriction. “I don’t see any reason why it should not last much beyond the lifespan of the existing [old] Pamban bridge [108 years],” Mr. Gaur said.

The commissioning of the new bridge on Sunday will also mark the resumption of train services between Mandapam and Rameswaram after more than 26 months as rail movement on the old bridge was suspended on December 22, 2022, and then cancelled permanently because of its poor structural stability.

Herculean task: The biggest challenge to the construction of the new rail bridge was the narrow approach road to the site from the Pamban side through which materials were transported.

| Photo Credit:

L. BALACHANDAR

How it works

While the old Pamban rail bridge had a Scherzer lift span that would open horizontally, the new bridge has been fitted with a vertical lift span, the first of its kind in the Indian Railways.

The new bridge of 2.08 kilometres only has a single rail track. But the 72.5-metre-long centre span has been provided with double broad-gauge lines. “Whenever the Madurai-Rameswaram section gets the second line, the new bridge will also get double lines; the sub-structure has a provision for the second line,” a railway engineer said. A provision for electrification has also been readied on the bridge. The vertical lift span alone weighs 654 metric tonnes. To lift the centre span for ship movement, two huge steel towers, 34 metres high, have been erected on both sides. The towers alone have been built with 1,470 tonnes of steel, including 620 tonnes of counter-weights (310 tonnes in each tower).

Electromechanical system

While the old bridge was lifted manually, an electromechanical system has been installed in the new bridge for lifting the centre span. The centre span has been connected to the two counter-weights with six steel-wire ropes each on four sides of the two towers. When the electromechanical system is operated, the motor would operate two sheaves (similar to a pulley) on the top of the towers.

With the difference between the weight of the centre span and the counter-weights being only 34 tonnes, the motors have to exert pressure to lift 34 tonnes alone. “With this provision, 95% of the weight of the vertical lift span is lifted by the counterweights, while only 5% of the work is done by the electric motors,” the engineer explained. While it took over 40 minutes to manually lift the Scherzer span up and at least 15 minutes to bring it down, the electromechanical system in the new bridge does the same work in 5.3 minutes each for upward and downward movement.

The centre span could be lifted to 17 metres. “With the bottom of the new bridge located five metres above the water level, the boats could have an absolute clearance of 22 metres to pass under the bridge. This clearance height is on a par with that of the road bridge across the Pamban channel,” the engineer said. The speed of lifting of the centre span and its height could be programmed in the SCADA software.

Request for lifting

Whenever the fishermen want to move their boats through the Pamban channel from the Kanniyakumari side towards the Nagapattinam side, they would make a request to the Port Conservator, who, in turn, would place a request to the Senior Section Engineer, Pamban Rail Bridge. “We would take a line block and lift up the centre span,” the engineer said.

Three anemometers, meant to measure wind speed, have been installed in the bridge, one each on pier 38, 77, and 78. The lift operator also has a handheld anemometer to measure the wind speed. “Whenever wind velocity goes beyond 58 kmph, the signal for train movement on the bridge would turn red and no train would be allowed to enter the bridge,” the engineer said.

The entire-stretch of 2.08 km of the new bridge has no signal to avoid stoppage of trains on the bridge. Signals have been erected on both the approach sides to the bridge. The trains have to stop only on the land to ensure safety of passengers. Whenever the wind speed goes beyond 80 kmph, the lift would not be operated.

As a stand-by for the Tangedco power supply for operation of the electromechanical system, two diesel generators of 650 KW capacity each have been installed. “Whenever power goes off, the generators would get switched on within six seconds,” the engineer added.

Bridge level increased

Since the girder and rails of the old bridge were laid over shorter piers, the water used to splash on them whenever the sea was rough. This was also contributing to the corrosion of the railway assets. Hence, engineers of the Rail Vikas Nigam Limited (RVNL) have raised the rail level of the new bridge by three metres, RVNL consultant S. Anbalagan said.

Published – April 06, 2025 12:56 am IST